Power steering is highly reliable and failures are rare so preventative maintenance is often neglected. Inspections should be done at every oil change and include checking fluid level and its cleanliness. Also look for leaks, damaged or worn pump pulleys, loose brackets, and drive belt condition and tension.

The fluid reservoir should be filled to the proper level. Low fluid level is a very common reason for hard steering while driving or parking, strange noises and increases in steering effort. Always use the recommended power steering fluid that is formulated for the task. This includes the ability to resist thinning at high temperatures; during parking fluid temperatures can reach 300 degrees F. Additives maintain good flow down to as low as –20 degrees F to prevent stiff steering on cold mornings. Fluid must be compatible with the rubber used in hoses and other components. Otherwise, hoses can deteriorate from the inside, causing small particles to flake off causing plugged strainers, sticky control valves and erratic behavior.

Inspect the fluid for dirt and sludge which are major threats to smooth operation. Shut off the engine, remove the filter cover and stick your finger in reservoir to feel for dirt sludge or particles. If fluid is dirty, flush the system before refilling with fresh fluid.

The drive belt must be checked for proper tension as specified in the manual. Poor tension will cause the belt to spin on its pulley. A slipping belt decreases the pump output and causes the system to operate erratically. An over tensioned belt will place excess loads on pump shaft bearing. Tighten loose belts. Other conditions to look for are splitting, edge/sidewall wear, grease or oil on the belt sidewall or in pulley grooves, or pilling that occurs when rubber compound from the belt wears off and settles in the V-grooves causing uneven rideout, vibration and belt noise.

On V-ribbed belts cracks along the width of the ribs are a sure sign the belt is in the later stages of life. If cracks extend down to the tensile cord, or if the belt is more than four years old, replace it. If the pulley slips or wobbles on the pump shaft, replace the pulley.

Hoses usually deteriorate from the inside first so they loose their effectiveness long before showing external signs of deterioration and leaking. Replace hoses if they have become hard and brittle. With age the hoses lose their ability to expand and contract properly and cracks appear. Also replace hoses if they have become soft and spongy - signs that the hose's inside has started to deteriorate. Oil and grease-soaked hoses are soft when squeezed and need replacement.

Look carefully for exterior wear such as that caused by abrasion and contact with metal parts. This can eventually wear a hole in the hose, causing it to burst under pressure. Not only replace the hose, but fix the reason for the damage by rerouting hoses, tightening brackets, using hose tie downs or placing rubber sheaths over the hose.

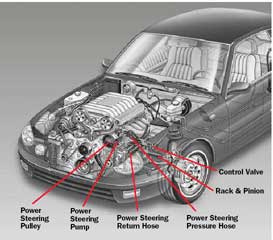

Power steering system hoses, generally fall into three categories - pressure lines, return and cylinder lines. Make sure to use the right hoses and do not try to get by with makeshift hoses, 'make do' repairs or the use of duct tape to 'seal' leaks. Pressure lines can be subjected to hydraulic pressures in excess of 1,200 psi. They are constructed differently from return lines that carry more no more than 50 psi. Pressure hoses are also subjected to surges in pressures and pulsation from the pump. Consequently, these hoses must be slightly expandable to reduce or absorb fluctuations.

Typical leak points include the reservoir cap, reservoir to pump body seal, the shaft seal, through bolts, fitting and hose connections. Leaking hoses, fittings, or seals will spurt fluid, when the system is operating, so inspect for wet spots. Power steering fluid must be at a normal operating temperature when tested for leaks. Run the engine with the tires on the ground and rotate the steering wheel from stop to stop, or left to right several times. The steering wheel should not be held in the extreme left or right position for more than a few seconds. Power steering conditioner products are often effective in stopping leaks, at least for awhile.

Finally, if you experience a problem with the power steering system, first check to make sure that it is the culprit and not another part of the steering system. The latter can include improper tire pressure, binding steering components, misalignment of the front end including improper caster or toe-in or merely the need for a chassis lubrication. If these are not the source of the problem, then investigate the power steering system.