Most people religiously change engine oil, engine coolant and transmission fluid, but never give a thought to their brake fluid. It is estimated that about half of the cars and light trucks on American roads over ten years old still have the brake fluid that was installed at the factory. Of all fluids in a vehicle, brake fluid most directly affects safety. Neglect engine oil and you risk your engine; neglect brake fluid and you risk your life.

|

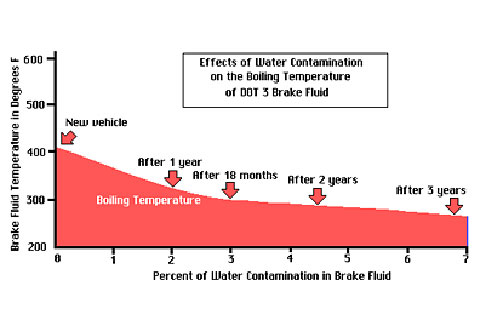

| How brake fluid degrades with time and moisture content. |

Most brake fluids are hygroscopic, meaning they readily absorb moisture from the air that gets into brake system past seals, via microscopic pores in brake hoses and from other sources of air that gets into the system. As the brake system heats and cools, condensation formed within the system can drastically reduce the brake fluid's boiling point temperature. When the fluid boils during severe brake usage, vapor lock can occur that greatly reduces braking efficiency. In the worst case, compressible vapor pockets replace brake fluid so that then when you hit the brakes, the brake pedal goes to the floor. Thus, moisture contamination is the reason that brake fluid gets old and why automobile manufacturers recommend brake fluid be replaced every two to three years.

The U.S. Department of Transportation has set the performance specifications for brake fluid that is accepted around the world. The original DOT and DOT 2 fluids were replaced by DOT 3 when disc brakes became common. High performance cars with antilock brakes needed a still better fluid, so DOT 4 appeared.

New DOT 3 brake fluid must have a boiling point of at least 401 degrees F, though most brands have dry boiling points of 460 to 500 degrees F. DOT 3 is considered wet or 'moisture-saturated' when the boiling point drops to under 284 degrees F. Only 3-percent moisture content can reduce the boiling point to 293 degrees F, very close to the minimum set by the DOT and the automakers. DOT 4 braking fluid has a higher minimum boiling points, at 446 degrees F when fresh and 311 degrees F when wet. While DOT 4 fluid absorbs water at a lower rate, the boiling temperature drops more drastically with increasing amounts of moisture. Here 3-percent moisture can reduce the boiling point by up to 50-percent.

After several years, brake fluid can contain 7- to 8-percent moisture. The problem is aggravated in wet and humid climates. With conservative braking, you probably will not notice the effects of high moisture content. However, under aggressive braking, you may find that moisture has taken its toll.

Moisture can also cause rust and corrosion which can pit master cylinders, steel brake lines, wheel cylinders, pistons and other critical brake system parts. If your vehicle has an anti-lock braking system, replacing corroded and pitted ABS modulators can be an expensive proposition.

There is also a DOT 5 brake fluid on the market. DOT 5 is a synthetic silicone fluid so it is not hygroscopic. However, DOT 5 does not completely eliminate the moisture problem because internal corrosion is still a big issue. Water that is heavier than silicone fluid will settle in low spots in the system. Here it can cause severe localized corrosion, freeze in cold weather or gasify at elevated temperatures. Thus, even DOT 5 is not permanent and it too should be replaced every year or two.

The downside of DOT 5 fluid is that it does NOT mix with DOT 3 or DOT 4. If you add DOT 5 to a system that already contains DOT 2, DOT 3 or DOT 4, the resulting mixture will dissolve the rubber 0-rings common to all hydraulic systems. Within a couple of hours the brake system will start leaking. Repair requires a complete system overhaul with all new rubber parts.

Since some DOT 3 or DOT 4 can remain even after serious flushing, DOT 5 should only be used when rebuilding the total brake system. Besides not absorbing water, DOT 5 doesn't 'eat' paint. DOT 3 and DOT 4 are great paint removers.

Because of the incompatibility of DOT 5, a higher-temperature-rated version of DOT 4 was developed mainly for the racing community. Somewhat confusingly, this fluid was designated DOT 5.1 even though it is compatible with DOT 2 through DOT 4 fluids. DOT 5.1 is hard to find, and isn't really needed unless you plan to do serious racing where brakes can glow red.

Unless the fluid is muddy brown, milky white or has rust particles floating in it, you won't be able to determine contaminated fluid by sight. However, there are ways professionals can test for contaminated fluid. Wagner Brake Products' WET CHECK test strips check the condition of the brake fluid. These chemically treated strips react to the moisture content in the fluid and change color if the fluid is good or needs to be replaced. A second color patch tells you whether you have DOT 3 or DOT 4 in the system. Phoenix Systems' STRIP DIP reacts to the presence of corrosion inhibitors in the brake fluid. A color scale rating ranges from 0 to 100 with a reading of 75 or higher indicating the corrosion inhibitors are depleted and the fluid needs to be changed. Electronic brake fluid testers measure the fluid's boiling point to determine the fluid's condition.

When replacing fluid make sure it is the one recommended for the particular vehicle. Also all brake fluid is not created equal so use a premium fluid, not one that just meets the minimum standards. The cheap stuff may not tolerate moisture absorption, provide the same corrosion protection or lubricate as well as a name brand.