Many of us have seen the poor soul stranded at roadside with a broken driveshaft hanging down under the vehicle. Perhaps it has even happened to you. To get going again usually means a tow, often an expensive one, to a garage for repairs. Periodic driveline inspections can prevent this from happening.

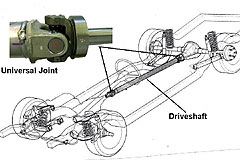

Most trucks, RVs, 4x4s and all rear-wheel-drive cars uses a driveshaft or propeller shaft. The shaft transmits power from the transmission to the differential where it is transmitted to the rear wheels. Since the transmission and differential constantly change their position relative to each other, at least two universal joints or U-joints are needed. On some vehicles, the driveshaft is divided into two sections so a second set of U-joints is used.

Driveshafts and U-joints usually are quite trouble free going tens of thousand of miles without difficulties. One of the biggest driveshaft problems is vibration. This usually occurs at higher speeds and the vibration can be quite violent if the unbalance is severe. Universal Joint failures usually occur when the bearings wear out.

If you experience propeller shaft vibration, first put the vehicle on a hoist and carefully inspect the driveshaft. Look for dents and other damage that can unbalance the shaft. Other sources of unbalancing include excessive rust, added or lost undercoating on the parts or missing balance weights. Also check to ensure clamps and fasteners are secure. You might consider removing the driveshaft and having professionally balanced.

You might find grease fittings on the U-joints for lubrication on older vehicles. However, today's U-joints do not usually require external lubrication. The first indication of U-joint problems is often clunking on accelerating or when changing gears. This is followed by squeaking, squealing and grating, but not for long since the U-joint will soon fail.

If you suspect an U-joint problem check the bearings in each joint. With propeller shaft still installed in the vehicle, turn the shaft with one hand while holding the adjacent part tightly. Any play indicates worn bearing and the need to replace U-joints immediately. Also inspect seals for damage, lubricant loss or excessive rust. If one set of U-joints is bad, replace them all while you have the driveline off the vehicle. You might find intermediate support bearings on some longer driveshafts. Check these bearings too for proper operation.

U-joints are designed to operate at maximum angles of 10 to 12 degrees. If these angles are exceeded for extended periods, the driveshaft can vibrate and U-joints are much more prone to fail.

Driveline angles are exceeded when the chassis height is lower than specifications. This occurs when the vehicle is overloaded, a trailer is improperly loaded or towed without a proper load leveling hitch, and if the springs on the vehicle need replacement.

Check the chassis height against specifications if you suspect overloading or improper loading. Specifications are available for many late model light trucks and utility vehicles. Also expect problems if the loaded vehicle bottoms excessively. Besides driveline problems, improper vehicle chassis heights can affect front wheel alignment leading to poor tire wear and even dangerous handling.