Today, several automakers offer supercharged engines. Others use turbocharged engines. What’s the difference, why are they used, and pluses and minuses? Both superchargers and turbochargers are used to obtain increased performance , that is more horsepower and torque.

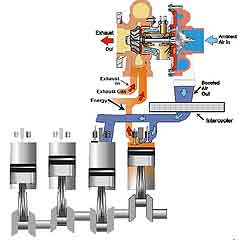

Superchargers and turbocharger uses an "air pump" to supply an increased air/fuel mixture to the engine than under normal, or non-aspirated, conditions. They increase the pressure, and therefore, the density of the air, delivered to an engine. This increases the mass of air drawn into the cylinders. Then, if the same air-to-fuel ratio is maintained, more fuel can be combusted to produce more power. A supercharger’s compressor is usually driven off the engine crankshaft either by belts or gears. A turbocharger, by a gas turbine is driven by engine exhaust gases. A turbocharger is technically a form of supercharger, that is a turbo-supercharger.

Superchargers were in use many years before the turbocharger primarily because it took longer to develop the materials needed for the turbochargers which operate at much higher speeds and temperatures. Supercharging is almost as old as the internal combustion engine itself. Rudolf Diesel produced a supercharger design in 1896.

Incidentally, virtually every diesel engine today, whether in a car or eighteen wheeler, is turbocharged today.

Much of development of early supercharging and turbocharging technology was for aircraft. Supercharger technology advanced during World War I to allow aircraft at higher altitudes as well as for extra power for takeoffs and climbing. Between the wars, early commercial airliners like Boeing 247 and Douglas DC-3 used superchargers so they could fly above the weather, and in the case of the Boeing 307 Stratoliner, to pressurize the cabin. In 1925, General Electric developed the first successful aircraft turbo-supercharger or turbocharger.

Aviation supercharging and turbocharging advanced substantially during World War II in aircraft like the B-17, B-24, P38 and P47. By the early 1950s, the piston engine had reached its zenith with the Wright Turbo-Compound engine that could produce up to 3700 horsepower and allowed airliners like the Douglas DC-7 and Lockheed Super Constellation to fly across the continent or the Atlantic nonstop.

Supercharging was picked up by auto racers by the early 1920s. Mercedes-Benz, Bentley Alfa-Romeo, Auto-Union, and others built winning supercharged race cars. In the U.S., supercharged Duesenberg and Miller cars raced at Indianapolis racers. Before World War II and the rich could buy supercharged Auburns, Cords and Duesenbergs.

Kaiser was the first US automaker to market a supercharged engined car after the war. Because didn’t have a V-8 to keep up in the horsepower race, used a supercharger to boost the output of its six-cylinder engine. Studebaker-Packard also tried to keep up with the Big Three's big-block V-8s by supercharging its small V-8. The 1962-1963 Oldsmobile Jetfire was the first production car to use a turbocharger, calling it the Turbo-Rocket. When working properly, the Jetfire gave flashing performance. More successful were the turbocharged 1962 to 1966 Chevrolet Corvairs.

By the mid to late 1970s, turbocharging, and to a lesser extent supercharging was a commonly used means to boost the power of small displacement engines. Smaller engines consume less fuel, weigh less, have lower frictional and pumping losses, and produce less emissions. Smaller and lighter engines are needed for today’s smaller vehicles with their smaller engine compartments as well as keeping total weight down.

Superchargers driven directly off of the engine rather than by exhaust gases are extremely responsive and instantaneously increase power. In contrast, the turbocharger’s turbine and compressor, take more time to be spun up to operating speed after the throttle is opened. This time is commonly referred to as "turbo lag." Engineers have done a commendable job in reducing turbo lag, but it has not been entirely eliminated.

Being mechanically driven, usually off of the crank-shaft via belts or gears, the supercharger is more complex. Thus it is usually more expensive to manufacture than a turbocharger. Likewise it often requires more modification to install on a vehicle and it is more difficult to find space in the engine compartment. By operating at very high speeds, turbochargers are very compact and require significantly less space in the engine compartment. However, new supercharger concepts are now appearing that rival turbochargers in the space they consume. Cost, ease of installation and space requirements have made the turbocharger more popular for aftermarket installations.

The supercharger is less efficient, drawing off more power from the engine and adding noticeably to fuel consumption. At first, it may seem that you are getting something for nothing with a turbocharger since it is powered by the energy of the exhaust gases which normally would be wasted out of exhaust pipe. However, the turbine in the turbocharger does increase the back pressure in the exhaust manifold that results in reduced engine power output. Fortunately, this loss of power in driving the turbine is relatively small in relation to the power increase obtained. Also there are frictional losses, mainly in turbine and compressor shaft bearings, though again these are relatively small.

Today, most turbochargers and superchargers are intercooled. A supercharger or turbocharger also increases the temperature of the incoming air. Therefore, intercoolers,an air-to-air or water-to-air radiator, is used to cool the air as it comes out of the compressor. The cooler air is denser, thus the air mass flow is further increased for more power. The cooler air puts less stress on internal engine parts and reduces pre-ignition and denotation pinging.