While radiator caps look simple and do not cost much, they are critical for a properly Operating cooling system. A faulty cap can result in overheating, loss of coolant or major engine damage, so it is important that it is checked periodically and replaced if necessary.

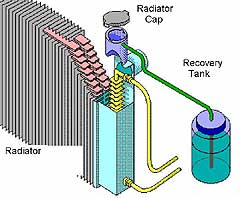

To prevent overheating and coolant loss, cooling systems are pressurized raising the coolant's boiling point about 3-degrees F for each additional psi above atmospheric pressure. The cooling system is pressurized as the engine warms up and the coolant expands. The radiator cap's pressure relief valve allows pressure to build up to a specified level, then lets excess pressure to escape. In an "open" systems found in older vehicles, excess pressure escapes to the atmosphere through an overflow tube. As the system cools, air enters through the overflow tube and coolant is lost. Therefore, "closed" or reservoir cooling systems are used in later model vehicles. Here, as the coolant expands it goes through the over- flow tube into a reservoir. The radiator cap now serves as a vacuum relief and siphon valve allowing coolant to be siphoned back into the radiator as the engine cools and the coolant contracts.

Radiator caps also serve as pressure relief valve to prevent excessive pressure in the cooling system after the engine is turned off. Unchecked high pressure could cause damage to the radiator, heater core, hoses or water pump seal. The pressure cap also prevents radiator hoses and tanks from collapsing due to the partial vacuum which would be created if air was unable to enter.

Check the radiator cap during routine maintenance, when coolant is tested or when coolant is replaced. Check only when the engine is cool. Then with the engine off, place a rag over the cap and remove it. Turn it counterclockwise about 1/4-turn until it reaches the safety stop. Allow all pressure to vent before removing the cap by pressing down and turning it counter-clockwise. On some vehicles, the radiator cap is located on the overflow reservoir.

Once the cap is removed, Pressure test the cap noting the maximum pressure when the cap valve opens. Caps come in a variety of pressure ranges: 4-pound caps (3-5 lbs.), 7- pound caps (6-8 lbs.), 13- or 14-pound caps (12-16 lbs.) and 15- or 16-pound caps (14-18 lbs.). The cap should be replaced if it fails to hold the rated pressure for one minute. Using a cap with the wrong pressure rating can cause over pressurization or too low a coolant boiling point if pressure rating is too low. Since radiator caps are so important and are relatively in expensive, why not just replace with a new one.

Also inspect the overflow tube connecting the filler neck to the overflow reservoir for looseness, cracking or obstructions. Check the radiator filler neck sealing surfaces for nicks, dents or corrosion that could impair sealing. Inspect gaskets for looseness, cracking, hardening or other damage that allow pres-sure leakage and coolant to escape.