Quiet Those Squeeling Brakes

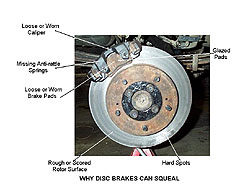

Squealing, squawking and squeaking brakes can not only be annoying, these noises can indicate potentially dangerous problems with your braking system. There are several reasons why brakes can be heard. Problems include worn out brake pads and shoes, the wrong pads have been installed or pads are glazed. Other reasons for squeals and squawks are warped or glazed brake rotors, misaligned or loose calipers, loose wheel bearings, or sticky pistons. If you hear clunks, metal-to-metal screeches or the brake pedal vibrates, you should check out the braking system immediately. The braking system is the most critical system on any vehicle.

The first step in silencing noisy brakes is to do a complete inspection of the braking system to identify the source of the problem. Look for excessively thin brake pads or shoes, scored or warped rotors and drums, brake fluid leaks and oil or grease on pads and shoes. Make sure pads and shoes have not worn down to the metal backing plate. If you do not catch the problem in time, rotors and drums can be grooved to the point they cannot be turned and will have to be replaced, usually an expensive proposition. Look for rust or corrosion that can prevent proper functioning such as a piston sticking in its cylinder. Check pads and shoes for equal side-to-side wear to determine if a piston might be sticking leading to unequal wear. If such an inspection and subsequent repairs are beyond your capabilities, take the vehicle to a qualified brake specialist.

Often the braking system checks out okay, but squealing persists. While probably not affecting braking safety and effectiveness, the noise can be irritating. If the squeal comes just as you about to come to a complete stop, often the reason is a brake pad that is vibrating against the rotor or caliper.

One solution here is to install vibration dampers. These are made of a self-stick fiber material which adheres to the back of the brake pad backing plate. Some damper designs are have a mushroom shaped button spring in the center that fits snuggly into the piston head. The fiber disk adheres to the backing plate of the pad to damp brake pad vibration while the mushroom button helps pull the pad away from the rotor as the piston retracts when the brake action ceases. This results in greater clearance between pad and piston that should eliminate vibration and squeal, but not always.

Another solution is to coat the back of the brake pads with an anti-squeal compound, a thick heat-resistant polymer adhesive applied to the back of the pad to provide a cushion between the pad and piston as well as help the pad retract with the piston. This material comes as an aerosol spray or as a liquid. Coat only the area that contacts the piston, making sure that it does not get onto the front, contact area of the pad or rotor, which would have the same effect as waxing your brakes. A good idea is to use both vibration dampers and either an anti-squeal or anti-seize product while you have brakes disassembled.

Another solution is to use the brake pads made of the right materials and designed to prevent squealing. Often squealing starts after you have replaced pads. That is because the OEM pads that originally came on the vehicle are usually quiet, but replacement pads are not as squeal resistant. The solution here is to use OEM replacements or try another brand.